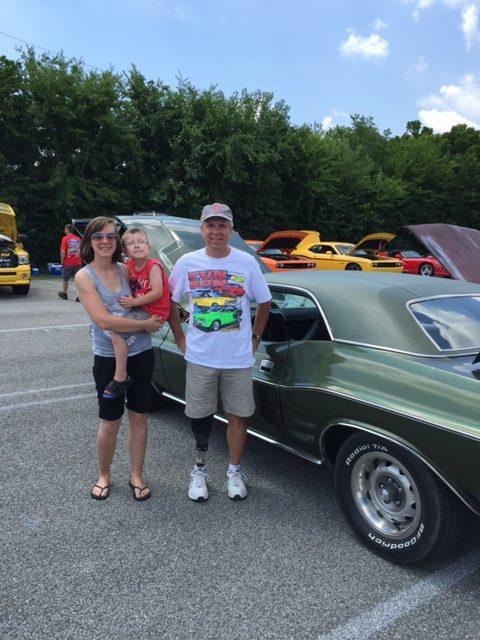

Apison, Tennessee native Randy Plank loved to be outside and walk five or six miles a day before a mysterious pain appeared in his lower right leg. Every time he walked, the pain would return, and he started having difficulty putting any weight on that limb.

“First, I went to a quick care clinic, and then they referred me to the hospital for an evaluation. I learned that I had problems with blood clots, which were the cause of the intense leg pain. Through that process, I was connected with a USA vascular surgeon,” says Randy. “It was a whirlwind few months, where they performed a few minor surgeries and put me on blood thinners to address the blood clots. Unfortunately, the clots didn’t move, and I needed a below-the-knee amputation.”

Randy worked closely a USA’s vascular surgery team through the initial procedures to relieve the blood clots until it was determined there was no more blood flow to his foot. That meant an amputation and recovery that lasted several months while the swelling in his leg went down. While in the hospital, Randy met with a prosthetist from USA Prosthetics who explained the process of being fitted for a prosthetic limb.

“Before my body was even ready to being fitting for my new leg, they let me come and observe the work they do with other patients so I could get a better understand of what was in my future. Knowing a little more about what to expect helped me feel more comfortable,” Randy says.

After he was fully recovered, Randy began the several-months-long process of fitting for his prosthetic leg. USA prosthetists began by making a plaster mold of Randy’s leg, which is done by hand. They wrap plastic around the leg, put plaster on it, then let the plaster set up before pulling it off his leg. This negative mold is used to make a positive. The next step is to create another mold out of clear, hard plastic. Randy wore this prototype for a few weeks to see how it fit and to determine what adjustments were needed. After completing the small tweaks, the prototype is sent off, and a permanent socket is created.

“The socket really is the most critical part of a prosthetic limb – the fit needs to be seamless, and it’s tricky to get it just right. I don’t think people realize how much customization is needed for the leg to be comfortable and work properly,” Randy shares. “Your limb also changes throughout the day and with the seasons, making the socket fit tighter and loser. That’s why there are specific fabric socks in different thicknesses that I change out to make everything fit properly.”

According to Randy, USA prosthetists Traci and Kevin and the whole team were great to work with from the start. They are always looking for ways to make things better for an amputee. They answered his questions, connected him with other amputees to ask questions and helped him feel comfortable and included in the fitting process.

“There are so many back and forth conversations and collaborations that are needed to get this right, and we worked together to come to specific conclusions about what the next steps should be. I’m also willing to try out new products and new limbs, working with Traci to help make things better for other patients, too,” he says. “We have a great relationship, and I’m grateful for what she’s done to help me get back to doing things I love. I can’t imagine anyone giving better service or having a deeper dedication to their patients than at USA.”

University Surgical Associates Prosthetics (USAP) is proud to offer an amputee advocate program for our patients, adapted specifically for new or pending amputees. You will be provided with an advocate (an amputee that currently utilizes a prosthetic device); one who can identify with your particular situation and offer advice, suggestions and encouragement. Advocates are carefully selected based on age, gender and type of amputation.

We work to make the transition to wearing a prosthetic as easy as possible, and a positive experience for both patient and family members. Learn more at universitysurgical.com/prosthetic-services.

Reading about Randy’s journey through overcoming health challenges and adapting to life with a prosthetic limb is truly inspiring. His resilience and determination to regain mobility highlight the importance of medical professionals and supportive care teams.